Innovative surface treatment solutions for the flexible electronics of the future

infinityPV is a Danish company with a strong international profile, specializing in the development and production of advanced solutions for printed and flexible electronic devices. With a focus on sustainability and innovation, infinityPV provides a wide range of laboratory and production equipment, including slot-die coaters, roll-to-roll coaters and precision manufactured slot-die heads. These technologies support the manufacturing and testing of advanced products such as flexible solar cells, printed batteries, fuel cells, LEDs, OLEDs and sensors. With strong expertise in slot-die coating and roll-to-roll processes, infinityPV positions itself as a leading provider of solutions for research and industrial manufacturing.

At Tantec, we pride ourselves on providing advanced coating solutions that can be easily integrated into infinityPV’s roll-to-roll and slot-die coating machines. Our equipment ensures optimal adhesion and high surface quality in the production of flexible electronic devices and components.

What is corona treatment and why is it important?

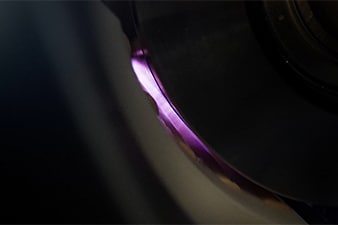

Corona treatment is an electrical surface treatment method that increases the surface energy of materials. This makes it possible to improve the adhesion of coatings, inks, adhesives and other materials on substrates that may otherwise be difficult to process, such as plastic, metal or composite materials.

infinityPV works with advanced technologies such as slot-die coating and thin-film coating, where the surface properties of the substrate play a crucial role. Without proper treatment, substrates can have too low surface energy, resulting in poor adhesion and thus degraded products.

Corona treatment ensures:

- Improved wettability: Uniform distribution of coatings and liquids.

- Strong adhesion: Improved bonding between substrates and coatings.

- Reduced defects: Better surface quality reduces the risk of production errors.

How does corona treatment work?

Corona treatment exposes the substrate to a high-frequency electric field (corona field) that ionizes the air around the material and changes the chemical structure of the surface. This makes the surface more susceptible to adhesion of liquids and coatings.

At Tantec, we offer specialized systems to suit different production needs:

- LabelTEC: Efficient for processing labels and flexible materials, particularly suitable for slot-die coating and roll-to-roll (R2R) processes, ensuring consistent surface quality that improves adhesion and supports precise coating results. Ideal for integration with infinityPV’s Laboratory Roll-to-Roll Coater.

- SpotTEC: Specialized in the precise treatment of small or complex surfaces, ideal for three-dimensional parts and detailed components. Perfect for roll-to-roll (R2R) processes and slot-die coating, enabling high precision in challenging applications where accuracy is essential. Perfect for integration with infinityPV’s Laboratory Roll-to-Roll Coater.

We know that every customer has unique needs and challenges in their production processes. That’s why we offer not only standardized solutions, but also customized coating systems tailored to meet specific requirements.

We work closely with our customers to understand their production environment, materials and applications.

The impact of the corona treatment on infinityPV’s production

infinityPV’s roll-to-roll machines and associated technologies require high surface energy substrates to ensure optimal performance in slot-die coating and thin-film coating. Tantec solutions are a key factor in achieving uniform material distribution and strong bonding in products such as:

- Flexible solar cells: Corona treatment ensures optimal adhesion and increases both efficiency and durability in flexible solar cells.

- Printed batteries: Improves adhesion between layers, increasing stability and capacity in printed batteries.

- Fuel cells: Increases the adhesion and durability of membranes in fuel cells to optimize their performance and lifetime.

- Printed LEDs: Creates an even and precise coating, improving the efficiency and reliability of printed LED components.

- OLEDs: Improves adhesion between the layers of OLEDs, which is essential for higher brightness and longer lifetime.

- Sensors: Increases the precision and reliability of sensors by ensuring a stable and efficient coating on flexible substrates.

Combining Tantec’s surface treatment with infinityPV’s roll-to-roll and slot-die coating machines creates a production platform that is both efficient and adaptable to different materials and product requirements.

The result of the collaboration between Tantec and infinityPV

By combining Tantec’s expertise in surface treatment with infinityPV’s advanced roll-to-roll and slot-die coating technologies, we create solutions that enable the development of high-quality products in flexible electronics. Our contribution results in:

- Increased product quality: uniform surfaces ensure better durability and performance.

- Efficient production: Reduced errors save resources and time.

- Flexibility in materials: The ability to work with advanced and complex substrates opens new opportunities for innovation.

This combination of technologies ensures that infinityPV can deliver highly specialized products while strengthening Tantec’s position as a leading supplier of surface treatment technology.

Contact us to learn more about how our collaboration can optimize your production and future-proof your products.