EPDM profiles with plasma treatment | ProfileTEC

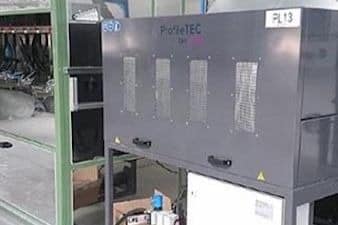

ProfileTEC

Two common applications for pre-treatment of automotive EPDM profiles with plasma are prior to the process of flocking and slip-coating.

In the flocking process, plasma treatment is necessary to achieve a strong bond between the rubber and the adhesive used to attach the flock. For slip-coating, it is necessary to treat prior to the spray process to achieve good wettability and optimum adhesion properties of the coating.

ProfileTEC eliminates the need for expensive primers, hazardous chemical treatments, or outdated abrasive brushing.

The treatment achieved through plasma discharge remains cost-effective without creating a threat to our environment.

ProfileTEC is manufactured to suit individual customer requirements and is designed for the treatment of conductive solid rubber, non-conductive sponge, or a combination of both types of material.

The free-standing systems are self-contained and offer 360° treatment at line speeds up to 40m/min. The ProfileTEC is available with single or multiple treatment heads and includes individual adjustment of each head, for max. operator flexibility.

Both standard and customized units are available with both single or multiple treatment heads. ProfileTEC conforms with CE regulations and carries the CE marking.

CASES

Technical specifications

| FEATURES: | |

| Easy to use | Connect to mains power and compressed air. |

| Modular plasma | Available with single or multiple plasma heads to suit any profile. |

| Interface control | All treatment parameters are delivered to the central PLC unit. |

| Minimum of maintenance | Minimal cleaning and parts exchange required. |

| Non-contact treatment | The plasma heads will not touch the profile resulting in mechanical damage. |

| Flexible design | The treatment heads are suitable for various materials eliminating the need to make changes. |

| Full integration | The profileTEC is easily installed into existing production lines. |

| Cost-efficient | Very limited running costs associated with the required power and compressed air. |

| Technical Specifications | ProfileTEC Plasma Treater |

| Mains voltage and frequency | 230 VAC, 50/60 Hz |

| Output voltage/plasma power | 400V/Max. 2000 Watt |

| Power supply | HV-X plasma generator series |

| Compressed air supply | 5-6 bar, dry and clean |

| Line-speed | Up to 40 m/min., others on request |

| Treatable materials | Conductive, non-conductive |

| System type | Stand-alone or table-top |

| Electrode positioning | Individual and no tools required |

| Regulation compliance | CE – RoHS – WEEE |