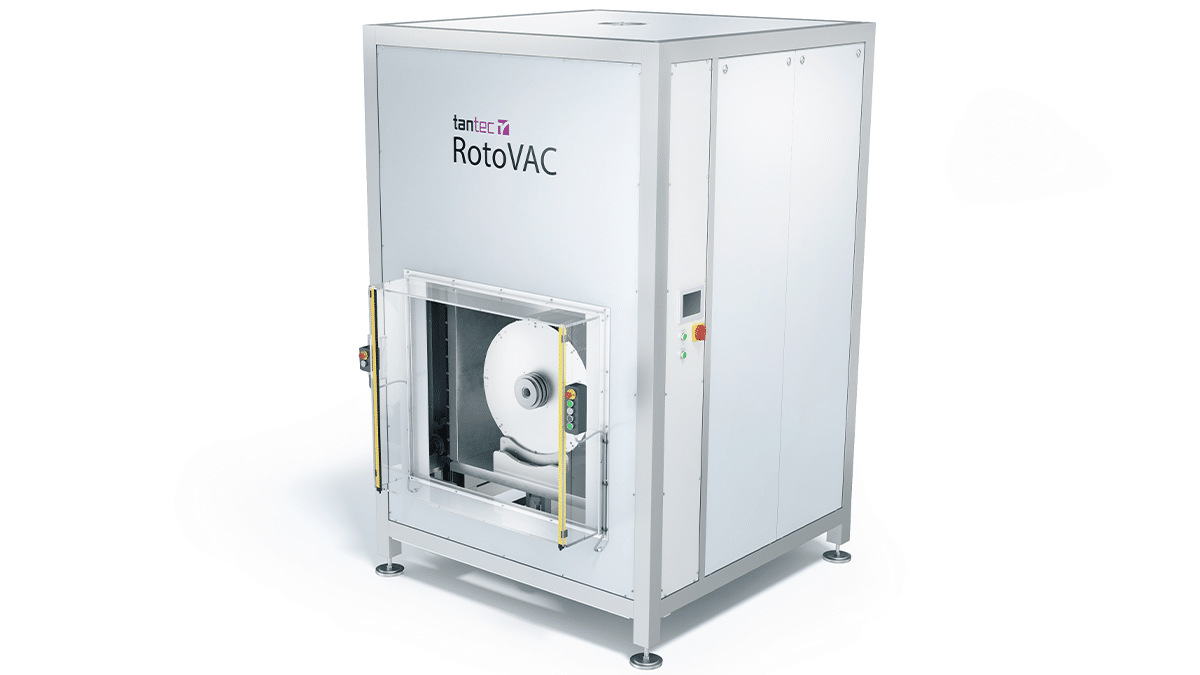

Vacuum Plasma Treater | Drum design | RotoVAC

RotoVAC

Tantec RotoVAC vacuum plasma treater is designed for plasma treatment of small injection moulded plastic parts, without the need to place them in a jig or use complicated handling systems.

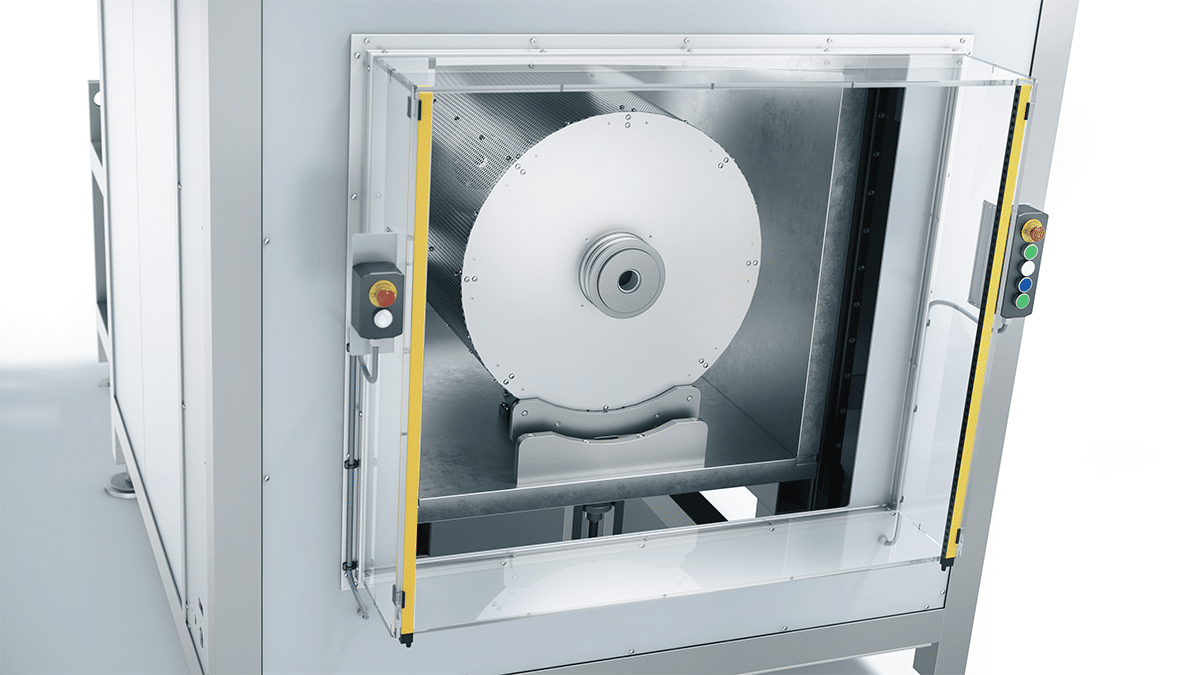

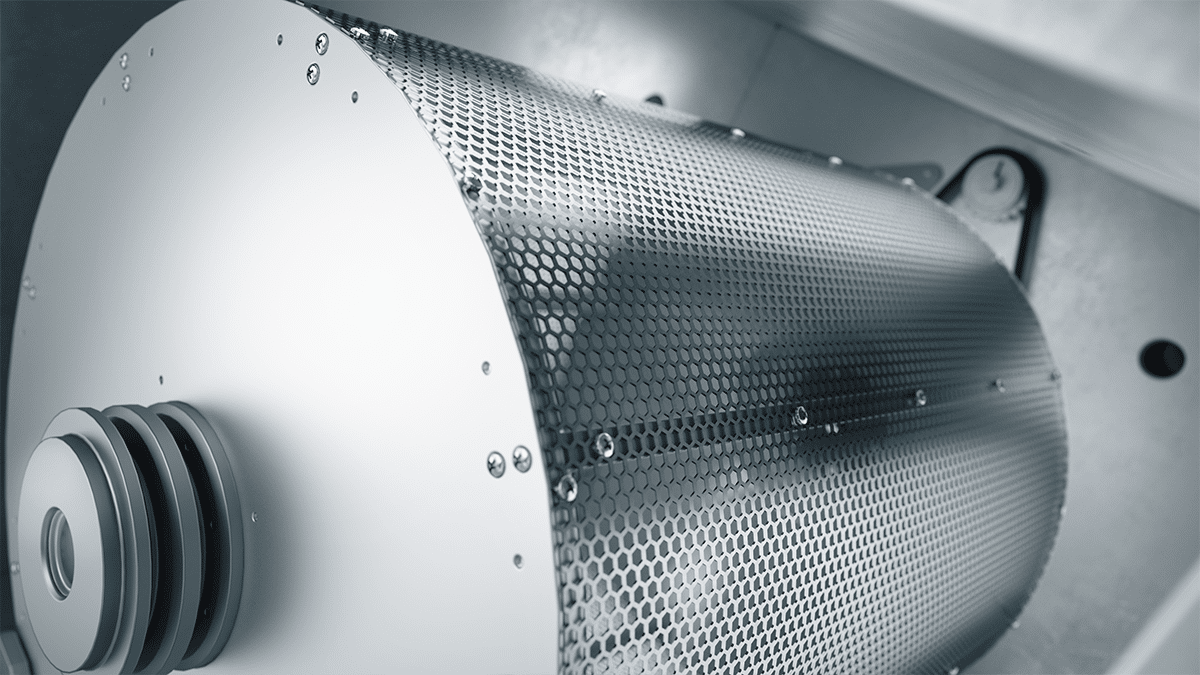

With the RotoVAC drum design, simply fill the drum and place it in the vacuum chamber. The rotation will ensure that all parts are treated.

In the treating chamber a vacuum builds up to between 0,1 and 4 mbar before an electrical discharge is created through the integrated plasma electrode. Treatment cycle times are often short, between 20-180 seconds depending on the material and its formulation.

The RotoVAC plasma treater is appreciated for its simplicity of operation, reliability in production and fast process speed. Treating gasses such as argon and oxygen can be applied, but in most cases this is not necessary due to the high power exposed by the plasma discharge. RotoVAC uses the advanced Tantec power generator HV-X series as power supply, and specially designed plasma transformers to provide voltage to the plasma electrodes.

The rotating drum ensures that all parts are equally treated. The concept includes an extra drum which can be loaded during treatment and simply exchanged with the one in use when the batch is completed.

Technical specifications

| FEATURES: | |

| Easy to install and use | Connect to mains power and compressed air. |

| Fast treatment times | High power impact enables treatment times from 20-180 seconds, depending on material. |

| Standard or customised chambers | Chamber and drum size can be designed to most applications. Many available as standard. |

| Vacuum level | The plasma discharge is active from 0,1-4 mbar depending on application. |

| Process gas | Process gasses such as oxygen and argon can be used, but in mostcases it is not necessary. |

| Process control | The entire plasma process is controlled by the HV-X generator and PLC unit. All parameters are displayed through the touch panel. (Standard – Proface). |

| Cost efficient surface treatment | Due to the low power and no need of special treatment gasses the unit is a very cost efficient solution for improving surface wettability and adhesion. |

| Vacuum pressure plasma | Enables treatment of both conductive and non-conductive surfaces. |

| Technical Specifications | RotoVAC Vacuum Plasma Treater |

| Mains voltage and frequency | 230 VAC or 480 VAC 3Ph. |

| Output voltage/plasma power | Max. 3,5kV/max. 2000 Watt |

| Power supply | HV-X plasma generator series |

| Compressed air inlet | 5–6 bar dry and clean |

| Process gas | Standard: air, oxygen, argon, nitrogen on request |

| Vacuum pump capacity in m³/min. | 15 to 240 m³/min., depending on size of vacuum chamber |

| Vacuum level | 0,1–4 mbar |

| Evacuation time, typical | 15-60 seconds, depending on chamber size and pump capacity |

| Plasma treatment time, typical | 20–180 seconds, depending on material |

| Control and connectivity | Complete with touch panel. (Standard – Proface) |

| Regulation compliance | CE – RoHs – WEEE |