Surface Treatment of Plastic Bottles – BottleTEC

BottleTEC

The importance of making the final packaging for a product look professional is an increasing trend at many bottle manufacturers. Manufacturers are focused on branding more than ever. Bottle manufactures do not want their labels to fall off the bottle or have logos printed poorly resulting in the product looking low end or poorly made. This can happen because the surface of the bottle has not been surface treated.

When bottle makers face label, coating and ink adhesion challenges corona surface treaters are often used to increase the adhesive strength. Bottle adhesion problems occur because many of the container materials used in the packaging are chemically inert.

Bottle coating ensures that labels are not peeled off until complete destruction of the label occurs. Surface treatment activates surfaces to create bonding sites to enable successful adhesion.

In simple terms, Surface Treatment (etching) is the preparation of a plastic surface to allow maximum adhesion between the plastic and other materials such as glue, inks, or coatings. Without this step in the production process the imprinted ink will run off and certain types of labels won’t stick.

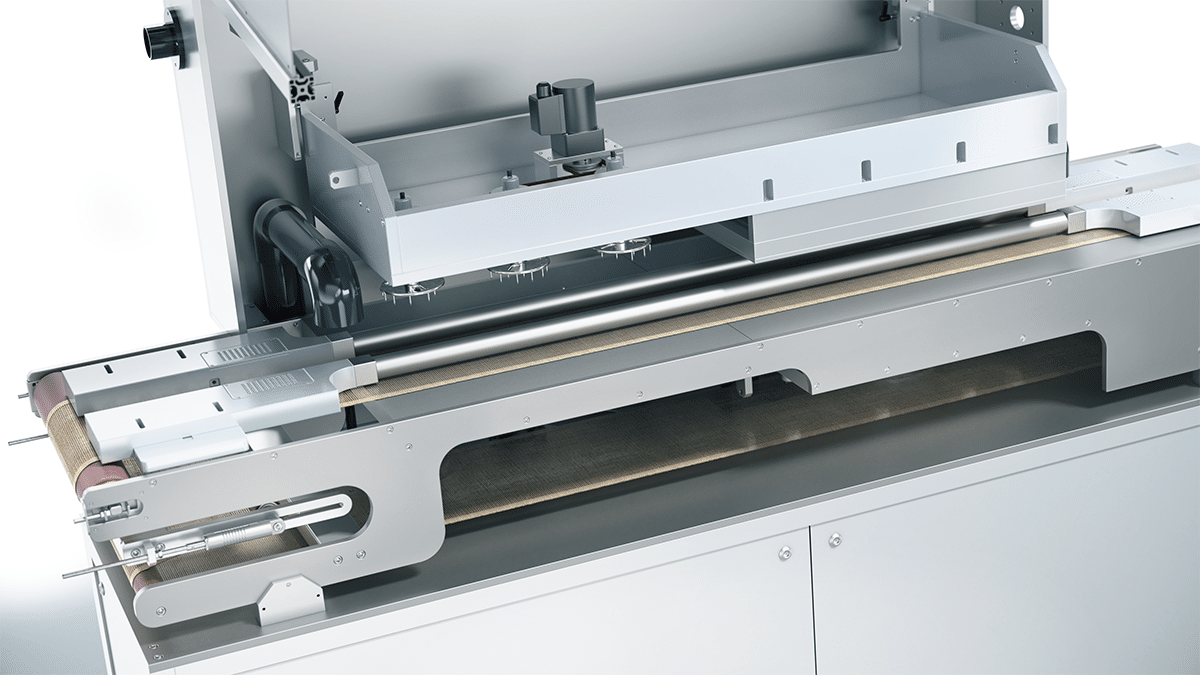

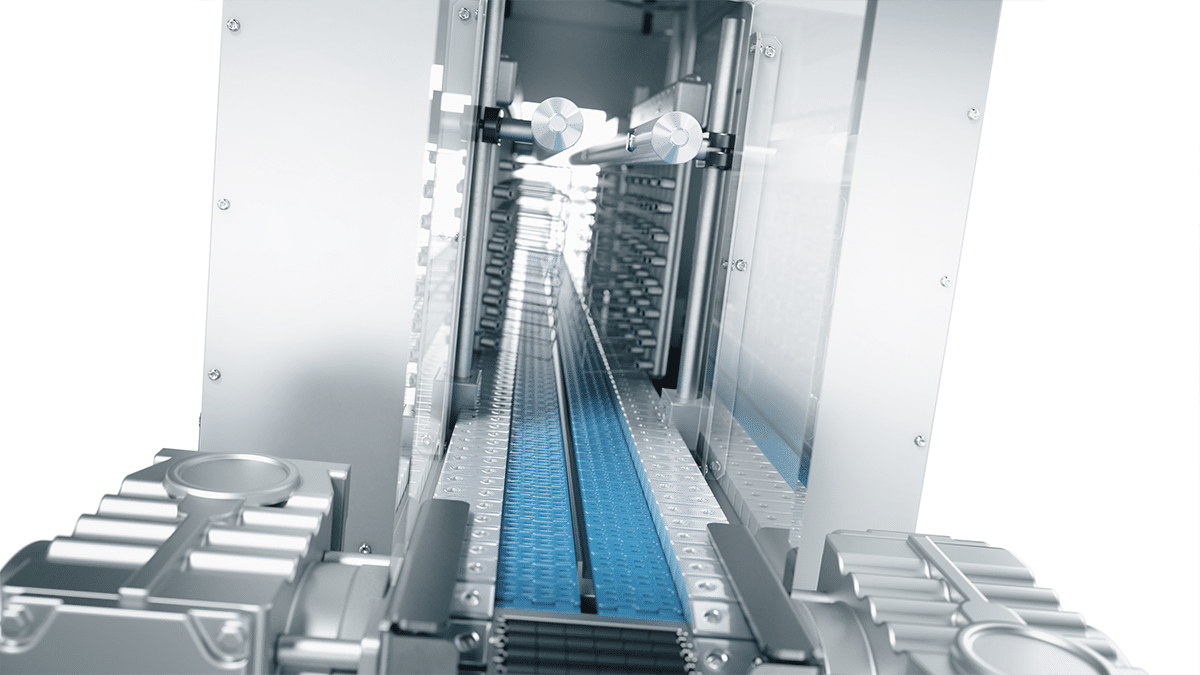

Tantec’s BottleTEC system sets new standards for corona treatment technology. It is possible to surface treat PE, PET, PP, PC, PEEK, ABS, PS and other cylindrical containers in high-speed molding, printing, filling or labeling production lines. Bottles quickly rotate through the system receiving 360° of treatment.

This universal BottleTEC system developed by Tantec operates with patented rotating electrode elements resulting in complete and uniform treatment of parts. These self-contained units can be installed within existing production lines or used as an off-line treating process.

Corona Treatment of bottles is considered an environmentally friendly process which has low operation cost. With Corona surface treatment you achieve great savings on adhesive materials, inks, coatings, and e.g. primer.

The BottleTEC Surface Treatment System features:

- Surface treatment of various shaped bottles

- Keeps pace with existing production lines.

- Treating levels up to 72 mN/m (dyne/cm) – depending on the application.

- Non-contact treatment

- BottleTEC electrodes ensure a uniform treatment

- Flexible design – no need to adjust

- Surface treating of empty and filled bottles (depending on application)

- Various design available depending upon part geometry

- Easy maintenance

Tantec’s BottleTEC surface treatment offers various solutions for improving surface adhesion of bottles. Our solutions include atmospheric plasma treatment and corona treatment. Some examples of our capabilities are shown below. Please contact us for further information.

Customized Corona system

BottleTEC – Corona Treater (Horizontal electrodes)

BottleTEC – Plasma Treatment with PlasmaTEC-X

BottleTEC – Surface Treatment with SpotTEC

BottleTEC – Corona Treatment (Vertical electrodes)