Atmospheric Plasma treatment system | PlasmaTEC-X

PlasmaTEC-X

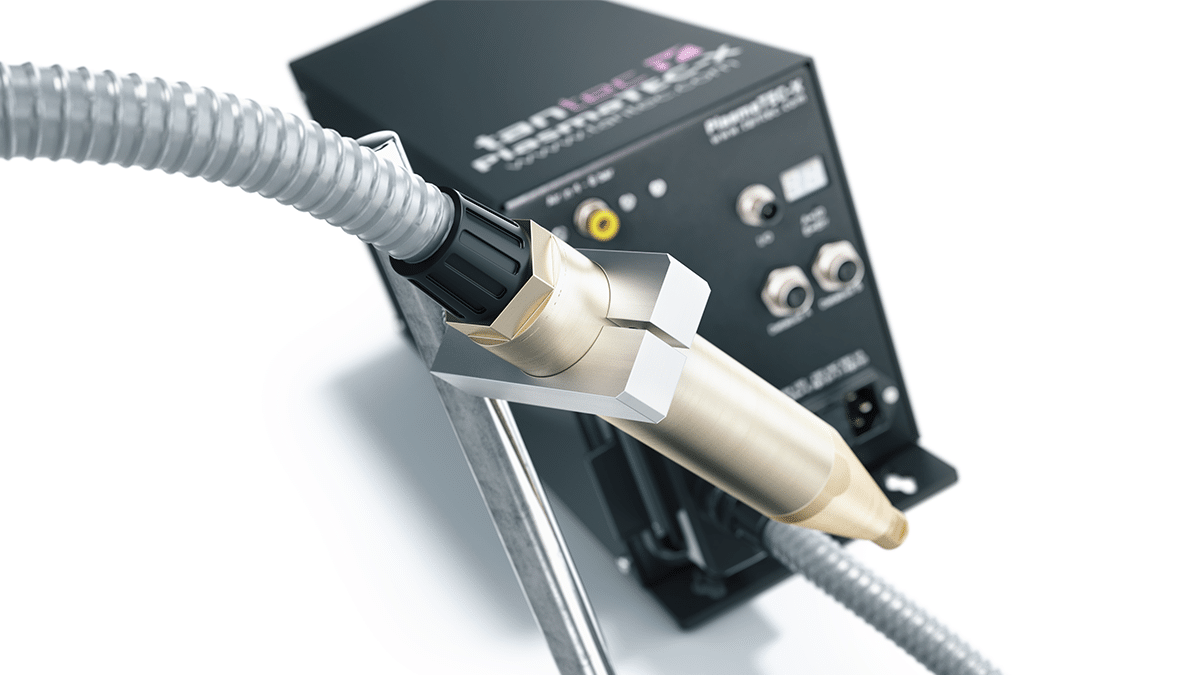

Tantec’s New PlasmaTEC-X Atmospheric Plasma treatment system is built around the concept of a high voltage DC Plasma discharge in atmospheric air.

The versatility of this unit allows for use in fully integrated robotic cells, as a standalone unit, or most any production line.

To ensure proper Plasma Discharge from the Discharge Nozzle the compressed air must be within a certain level of pressure and volume, the new AirTEC system, which is built into the PlasmaTEC-X ensures a constant flow to the Discharge Nozzle at all times.

With the AirTEC System, the plasma generator automatically adjusts the airflow of the Discharge nozzle regardless of the cable/hose length.

The AirTEC System in conjunction with the universal power input makes the PlasmaTEC-X very user-friendly. No adjustments are necessary, simply connect to the power grid (mains power) and compressed air and the unit is ready for use.

A Daisy Chain system is offered where any combination of 1-8 PlasmaTEC-X Plasma Generators can be controlled through a single control unit – the PlasmaREMOTE HMI unit. The units can be controlled individually through a conventional relay system or from the digital interface as a group with the same master signal.

Tantec’s latest feature, which is now being offered, is called “Stand-By air low.” Through the HMI, an operator can set an airflow during standby to avoid dust being attracted to the discharge head.

All connections from the PlasmaTEC-X Plasma Generator to the discharge nozzle is made through a standard plug, making it very easy to connect and use.

Thanks to the DC technology, and the AirTEC system, no adjustments are necessary in case of cable length changes.

Technical specifications

| FEATURES | |

|

Easy to install The system must be connected to mains power and compressed air, no adjustment of air or power is necessary. |

Standby air flow The airflow is controlled electronically which allows for switching the on/off, A minor flow of air is part of stand-by, to avoid dust being attracted to the discharge nozzle. |

|

Potential free discharge Allows treatment of both conductive, non-conductive as well as semi-conductive surfaces. |

Compact and Lightweight Being compact and lightweight makes the PlasmaTEC-X easy to integrate into almost any production line or robot cell. |

|

High-speed production High power Plasma Discharge allows for high line speeds. |

Output discharge control Should the power drop below a pre-set level, the generator offers necessary alarm signals. |

|

Control signals A large number of various signals are available on a digital interface to control and monitor the Plasma discharge at all times. |

PlasmaREMOTE An HMI Control unit offers easy control and adjustment of parameters. The HMI Control unit can monitor and control from 1-8 units of the PlasmaTEC-X. |

|

Automatic discharge air regulation No matter the length of the power/air cable, the Plasma generator will adjust automatically to ensure the correct air pressure and flow. |

| Technical Specifications | PlasmaTEC-X Generator | PlasmaREMOTE | PlasmaTEC-X Nozzle |

| Mains voltage and frequency | 100-250VAC – 50/60Hz – (Universal power input) | N/A | N/A |

| Output voltage/power | 550VA | N/A | 425watt |

| Ramp-up time | 10 ms | N/A | N/A |

| Shut-down time | < 1 ms | N/A | N/A |

| Control interface | M12 (8 pole) | M12 (4 pole) | N/A |

| Dimensions (WxLxH) mm | 150x470x198 | 125x169x167 | OD30x206 |

| Weight in kg | 6,1 | 2,0 | 1,1 – (w. 2 mtr hose) |

| Treatment width in mm | N/A | N/A | 6-12 mm |

| Compressed air supply | 5-6 bar, dry and clean | N/A | N/A |

| Compressed air connection | OD8mm – Quick connection | N/A | N/A |

| Air consumption | N/A | N/A | 33 ltr/min |

| Units per PlasmaREMOTE | N/A | 1-8 PlasmaTEC-X – generators | N/A |

| Regulation compliance | CE – RoHS – WEEE | CE – RoHS – WEEE | CE – RoHS – WEEE |

Solving your adhesion problems

We have more than 50 years of experience in delivering and manufacturing quality, high-end surface treatment products for any industry.

Tantec has both standard machines, but also custom-designed machines.

Contact us today and get a quote. We are standing by to service you.

Solving your adhesion problems

We have more than 50 years of experience in delivering and manufacturing quality, high-end surface treatment products for any industry.

Tantec has both standard machines, but also custom-designed machines.

Contact us today and get a quote. We are standing by to service you.

Solving your adhesion problems

We have more than 50 years of experience in delivering and manufacturing quality, high-end surface treatment products for any industry.

Tantec has both standard machines, but also custom-designed machines.

Contact us today and get a quote. We are standing by to service you.