Knowledgebase/FAQ

FAQ – all you need to know about surface treatment

The future of adhesion. The (perhaps) only way to green surface treatment

Sustainability is no longer a luxury. It’s no longer a nice-to-have. In the medical industry, automotive industry and other quality-dependent sectors, the demands for…..

The Importance of Surface Treatment in the Medical Industry

In the medical industry, the success of many processes and applications depend on the ability of various materials to adhere to each other.

Plasma and Corona Treatment in the Medical Industry

In the medical industry, adhesion and coating is definitely a challenge on low surface-energy materials like polystyrene, polypropylene, polyethylene.

How to treat and prove adhesion on medical devices

Surface treatment plays a crucial role in the medical device industry, particularly when it comes to enhancing adhesion properties and improving surface energy.

Improve Surface Energy | Compare Corona & Plasma

What is surface energy, and why is it important to have high surface energy when bonding prints on surfaces?

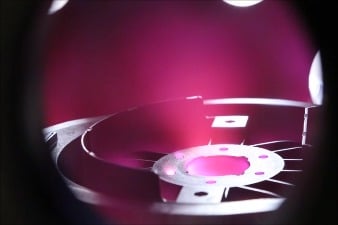

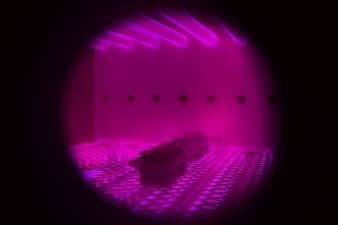

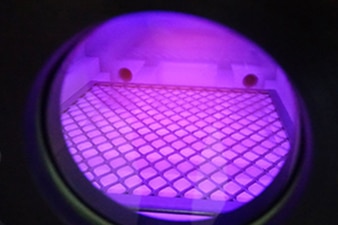

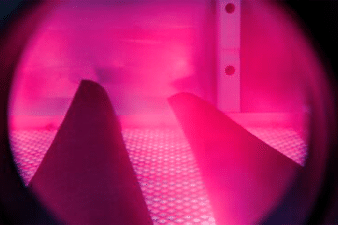

Vacuum Plasma Technology - webinar

Vacuum plasma is a suitable technology when your product or part requires treatment to all surfaces. Even 3D parts with..

What is surface treatment?

Surface energy of solid materials and the need for surface treatment of polymers. It is often necessary to bond plastic materials to metals or other plastic materials, or…

The Process of Plasma Etching

Etching is the process of removing a material from the surface of another material. There are several methods of plasma treatment, but two main types…

What is Plasma Cleaning Used For?

Cleaning is required for the removal of contaminants from surfaces before they can be used in the manufacturing process. Plasma cleaning can…

Plasma Etching and the benefits over Liquid Etching

One way to modify the physical and chemical properties of metals is plasma etching. The technique is particularly popular in the digital world for the…

Adhesion and Surface Treatment of Plastic

Surface treatment of plastic is not an uncommon procedure in the industrial world. Innumerable plastics are treated each and every day for improved wettability…

The basics of plasma treatment

Until the 1950’s, matter was thought to exist in only three forms i.e. solid, liquid, and gas. But all that changed when a Danish engineer discovered plasma…

Basics of corona treatment

Corona treatment was introduced in the industrial sector in the year 1951. An engineer in Denmark was requested to find a secure way for apposite printing…

5 reasons for using plasma or corona

Vacuum plasma is a suitable technology when your product or part requires treatment to all surfaces. Even 3D parts…

Plasma in a bag: How do you treat the inside of a closed plastic bag?

Tantec Plasma Treatment equipment has many different applications. As an example, in the medical industry, we have solved many problems with our machines…

How long are plasma activated polymer surfaces open?

To improve the adhesion of polymers, a needs-oriented surface pretreatment can be performed using a plasma process….

Surface Treatment of metals

Treatment of metals can be of essential importance in many industries. It is not a new proces, but a proces that dates back as early as…

Vacuum Plasma Treatment Improves Adhesion Capabilities

The results of plasma treatment of surfaces are present in your everyday life, even if you aren’t aware of it. Just look at the keyboard on your computer – chances are…

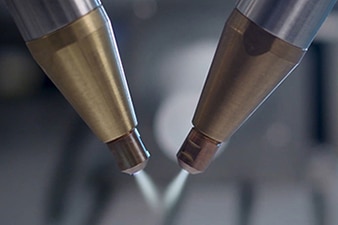

Understanding the Differences Between Corona and Plasma Treatment

One of the most frequently asked questions at Tantec is: “What is the difference between corona and plasma treatment?” This article aims….

What is the difference between reactive ion etching and plasma etching?

In this article, we will discover the fundamental principles and applications of reactive ion etching and how it contrasts with other etching techniques like plasma etching.

Why use Tantec high end equipment for corona treatment of plastic

Tantec’s advanced corona treatment technology enhances plastic adhesion, durability, and print quality across industries. Discover how we deliver tailored surface treatment solutions for packaging, automotive, medical devices, and more.

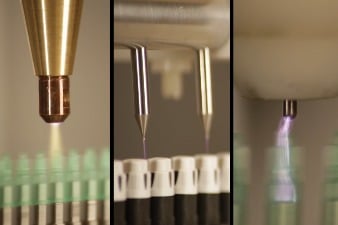

What is corona surface treatment?

Corona treatment is a high-frequency, high-voltage electrical discharge. The discharge is generated between an electrode and a counter electrode. The corona discharge has such a powerful impact on the substance surface that the molecular structure changes in a way that improves the surface wettability.

Is it possible to treat metal surfaces?

Metal surfaces can be treated by using special insulated electrodes. Treating metal surfaces is primarily a surface cleaning issue.

How can the improved adhesion be measured?

The improved adhesion strength can easily be measured either through contact-angle measurement or by using dyne inks.

What does dyne level / mN/m mean?

The dyne level reflects the surface wettability – the higher the dyne level, the better the wettability/adhesion.

Read more about Dyne test.

Can Tantec equipment be built into my existing production line or is it always a batch process?

Does line speed affect the results of corona treatment?

Yes, the higher line speed, or the higher throughput of products, the more Corona power is required. Tantec can easily calculate the need of treatment power, and specify the number of electrodes and size of Corona Generator.

Is any extraction required from a Corona treater?

Yes, ozone is formed as a by-product of the corona-discharge process. It is an allotropic form of oxygen, and exists at room temperature as an unstable gas with a sharp, characteristic odour. It can usually be detected by its odour at concentrations as low as 0.01 to 0.05 ppm, which are below the permissible exposure level of 0.1ppm. Tantec supply a standard range of ozone filters with flow sensors to control extraction air flows, and Tantec guarantee the ozone level in the working area is not exceeding the permissible exposure level.

Does Tantec offer after-sale services?

Tantec offer start-up of equipment and training of operator personnel at the customers site, and Tantec technicians are available for annual maintenance service on supplied equipment.

In this section you will find technical articles about our plasma and corona technology.

We understand, that it can be difficult to understand what plasma and corona exactly are, how the technology works, and to which materials it can apply. The Tantec knowledgebase category, (or Frequently Asked Questions/FAQ), contains technical articles about the technology and the processes.

Many of the articles we present here, are a result of the questions we receive through our website or from our clients around the world, who we meet at exhibitions or at our technology seminars. A question we often encounter, is how plasma treatment can work as an etchant. Please read more about that in our article about Plasma etching.

We hope you find answers to your questions here. If not, do not hesitate to contact us, and we will provide you with an answer as soon as possible.

Reasons to surface treat materials

It is often necessary to bond plastic materials to metals or other plastic materials or simply print on a plastic surface. In order to successfully accomplish this, the liquid adhesive, or ink should be able to wet the surface of the material. Wettability depends on one specific property of the surface: Surface Energy, often referred to as Surface Tension.

Tantec develops, manufactures and markets innovative Corona Treaters and Plasma Treaters to improve adhesion properties on plastics and metals, by raising this surface energy.

When the surface is treated the gas starts to flow at a low pressure. All this happens before any energy (electrical power) is applied. Plasma treatment at low temperature can easily process materials that are heat sensitive. These types of plasma is sometimes referred to as `cold plasma´, which means cold plasma treatment.