Plastic products treated with Corona Treatment | RotoTEC-X

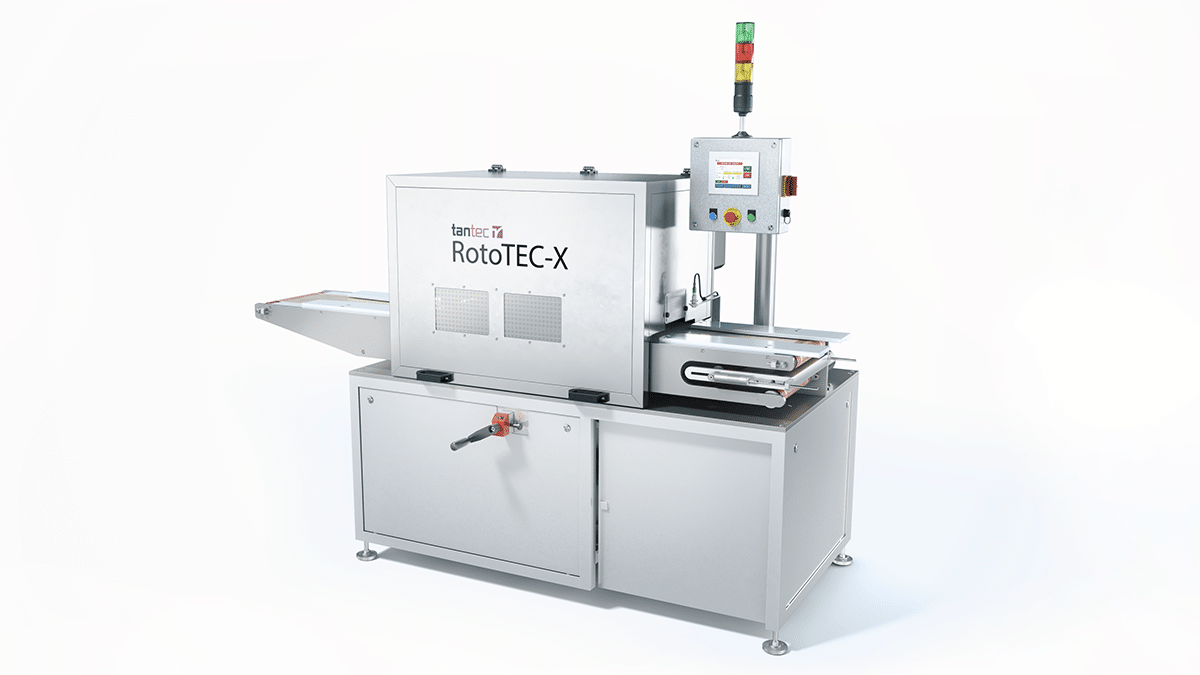

RotoTEC-X

Tantec RotoTEC-X is used for in-line treatment of injection molded parts prior to coating, printing, gluing, painting, etc. Often the RotoTEC-X is also used simply for optimizing adhesion properties of a given substrate.

The RotoTEC-X ensures a very uniform treatment process and offers the user full process control of all parameters.

The RotoTEC-X corona treater offers a cost-effective method for optimizing the adhesion properties of printing inks, coatings, glue, and paint on any surface made of polymer material including the commonly used polypropylene and polyethylene. RotoTEC-X can thus be used for treating plastic materials and plastic products.

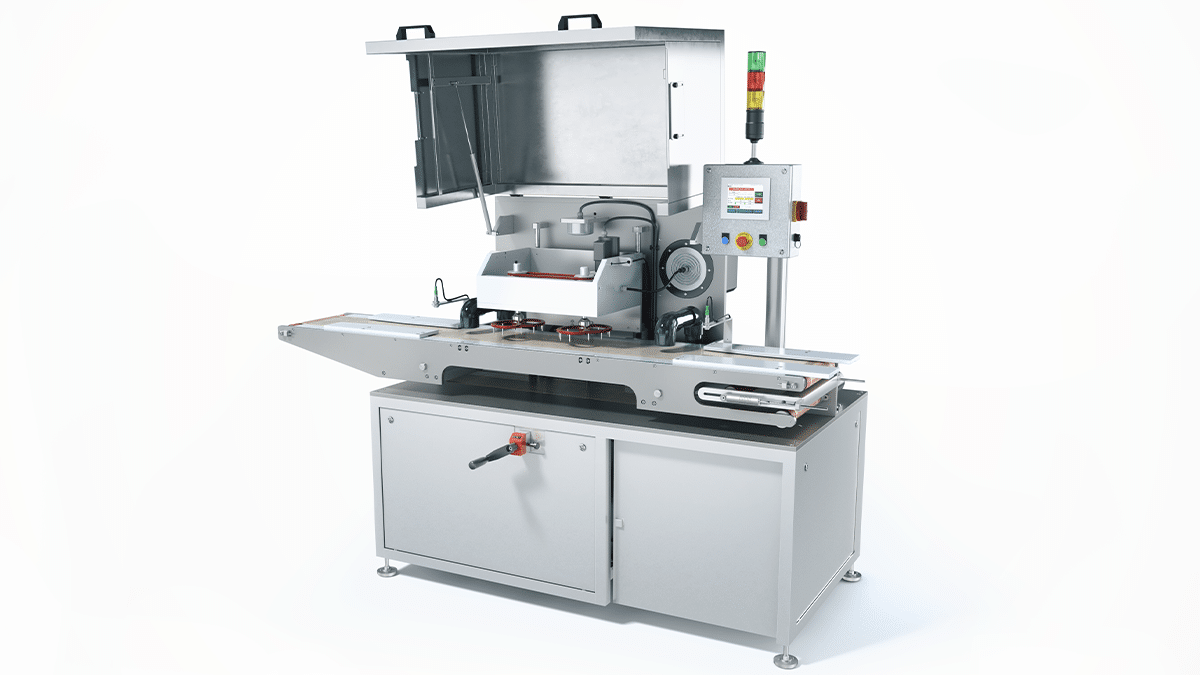

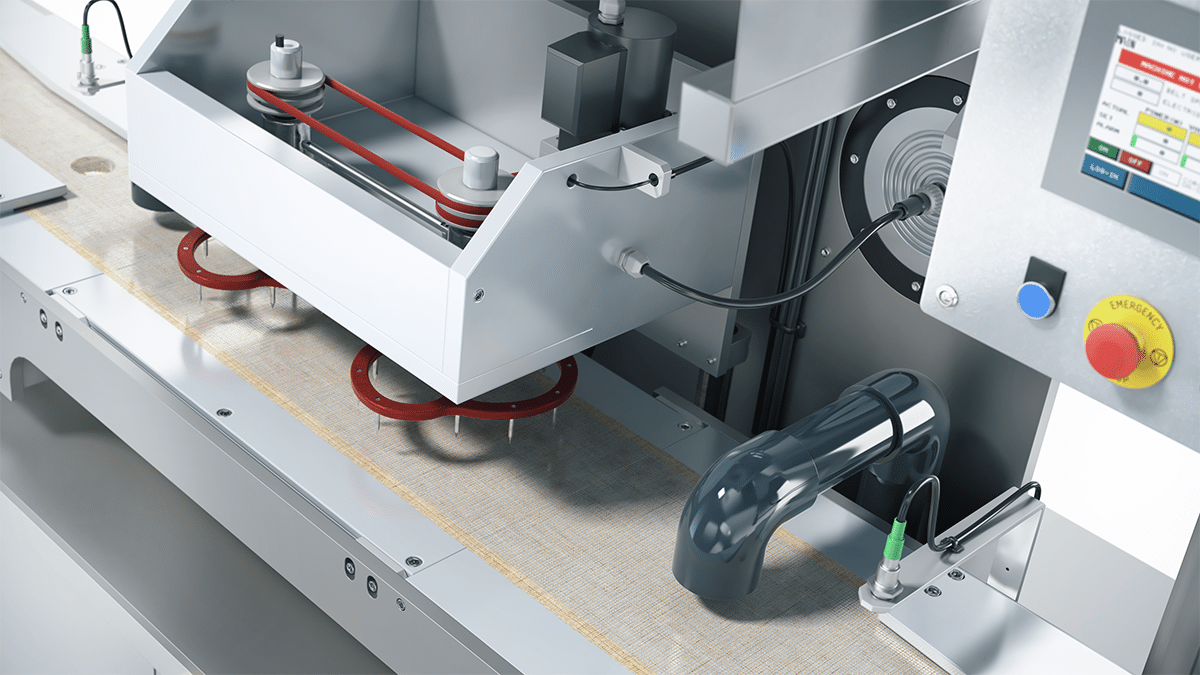

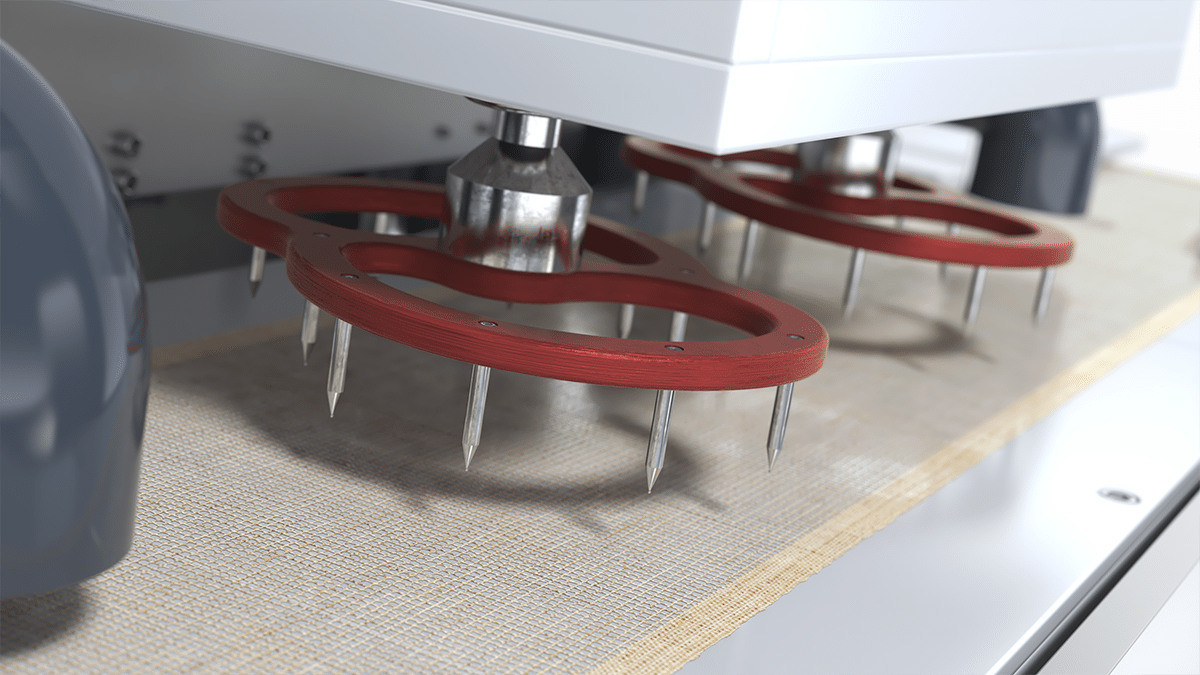

This universal system developed by Tantec operates with patented rotating electrode elements resulting in complete and uniform treatment of parts. These self-contained units can be installed within existing production lines or used as an off-line treating process.

The system includes a high- frequency generator, high-voltage transformer, rotary electrodes, ozone filter, and customized stand-alone or bench-top treating station. Both standard and customized RotoTEC-X stations are available for both single and dual-sided treatment.

Cases

Technical specifications

| FEATURES: | |

| Non-contact treatment | No need for electrodes to touch the part surface. |

| Treatment of parts | Various designs available depending upon part geometry. |

| Fully guarded treating station | Complete unit with all necessary safety precautions observed. |

| Touch panel | All parameters are displayed on the touch panel and are easily adjusted. |

| Uniform treatment levels | Rotating electrodes ensure a uniform treatment. |

| No need to change electrode height or set-up | Flexible design for multiple part treatment – no need to make adjustments. |

| Line speed up to 15 m/min | Keeps pace with existing production lines. |

| Patented design | RotoTEC-X electrode design offers optimized uniformity at treatment. |

| Technical Specifications | RotoTEC-X Corona treater |

| Mains voltage and frequency | 230 VAC 50/60 Hz |

| Output voltage/plasma power | Max. 400 Vp/Max. 2000 Watt |

| Power supply | HV-X plasma generator series |

| Line speeds | 0.5-15 m/min |

| Treatment sizes | Up to 100 mm high and 2000 mm wide |

| Treatment area | Single or dual sided treatment |

| Treatable plastic materials | PP, PE, PEEK, ABS, PC, PS and others (non-conductive only) |

| Transport system | Flat belt conveyor and o-ring belts |

| Control and connectivity | Complete touch panel. (Standard – Proface) |

| Regulation compliance | CE – RoHs – WEE |