Vacuum Plasma Treater | VacuTEC 8080

Standard VacuTEC system with customized chamber sizes. There are so many possibilities. Tantec has both standard VacuTEC machines, but also custom-designed machines. The VacuTEC customized machines are specially developed and adapted 100% to customer wishes and requirements in relation to the production line.

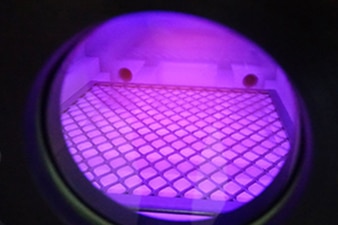

Tantecs VacuTEC Series Plasma Treater is designed for treatment of a large number of different injection moulded parts. The

VacuTEC offers very fast treatment times and optimum adhesion properties for downstream coating, gluing, painting and printing applications. In the treating chamber a vacuum is built up to between 0,1 and 3 mbar before an electrical discharge is created through the integrated plasma electrode.

Treatment cycle times are often short, between 5 – 60 seconds depending on the material and its formulation. VacuTEC uses the advanced Tantec power generator HV-X series as power supply and specially designed plasma transformer to provide voltage to the plasma electrodes.

Cases

Technical specifications

| Technical Specifications | VacuTEC 8080 | Vacuum Plasma Treater |

| Output voltage/plasma power | 5kV / 1200W |

| Power source | HV-X20 generator |

| Compressed air inlet | 6 bar dry & clean |

| Treatment gas | Standard air, (option oxygen, argon, nitrogen on request) |

| Vacuum pump capacity | 300 m³/hour (recomended), others on requset. |

| Vacuum level | 0,1 – 3 mbar |

| Evacuation time, typical | From 40 sec, depending on pump. |

| Plasma treatment time, typical | From 20 seconds, depending on material |

| Electrical Controls | Tantec HMI touch panel. |

| Regulation compliance | CE – RoHS – WEEE |

| Chamber volume | 624 Liter |

| Treating volume | 2 x 128 Liter |

| Tray size | 800 x 800 x 200 mm |

| Shelves | 2 |

| Pump placement | Standard behind, (option on top of VacuTEC) |

| Dimensions (W x D x H) | 1450 x 1280 x 2225 mm |