High level of service and close dialogue with Tantec and the Czech agent Meritage made the difference

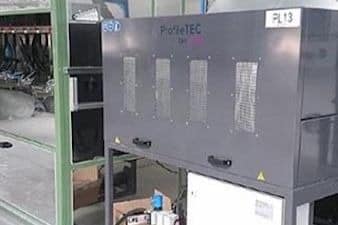

Close cooperation, constructive dialogue and a cost-effective solution made the difference for SaarGummi, which ultimately chose that many production lines would switch to Tantec’s ProfileTEC solution.

SaarGummi is one of the world’s leading manufacturers of dynamic seal profiles for inner door seal profiles and specializes in sealing solutions for the global automotive industry.

Tantec’s plasma solution is installed in an extrusion line where EPDM sealing profiles are surface treated before the items are coated.

For more than 10 years, Tantec has provided custom-built ProfileTEC solutions for the EPDM industry, and the many years of experience combined with low cost solution made the difference. Technical Director at SaarGummi Martin Šmíd comments: ”Tantec’s agent Meritage, with their broad experience, spare parts safety and high quality of service, did not make the choice difficult for us. The constructive dialogue with Tantec A/S and the price level of ProfileTEC solution was at the same time in an attractive lease.

After the first solution was implemented and tested, many production lines were replaced with ProfileTEC.

Customized designs

Tantec design customer-oriented solutions for in-line production. Our ProfileTEC offers sustained continuous operation with first-class results. It ensures that the further processing can occur in the most optimal way.

The ProfileTEC completely replaces processes such as roughening up, fluoride treatments with gas or the use of primers. ProfileTEC consumes less energy in comparison with the industry average, and this makes itself apparent not only during the initial investment stage, but also in reduced long-term running costs.

ProfileTEC includes a modular electrode system made in non-corrosive materials, featuring a minimum of wearing parts and a compact design.

A customised ProfileTEC usually consists of 4-16 treating units (heads) and is capable of handling high line speeds (up to 30 meters per minute depending on the type of profile) and complex parts made of conductive and non-conduc¬tive rubber. The system increases the surface tension from 34 to 50 mN/m – which is the tension level required for the best adhesion possible today. The system can be used both in the extrusion line and in fabrication.

Specifications ProfileTEC:

ProfileTEC can treat all kinds of profiles, including:

ProfileTEC can treat all kinds of profiles, including:

- Door weatherstrips

- Inner and outer beltstrips

- Secondary seals

- Quarter window weatherstrips

- Decklid seals

- Roof rail weatherstrips

- Glass run weatherstrips

- Windshield moldings

- Hood-to-cowl weatherstrips

The advantages of using this technology with EPDM applications are as follows:

- High processing speeds (up to 25 m/min, depending on the die), higher on request

- Area pre-treatment using homogenous corona discharge

- Gentle pre-treatment process (no surface burns)

- Large process window (important with groove geometry, because surface and groove floor are treated evenly

- Low energy consumption, 2000 – 4000 W

- Flexible electrode set-up, for quick change and adjustment

- Pre-produceable treatment process with microprocessor controlled generator technology