Lynddahl improves microduct quality with Tantec’s PlasmaTEC-X solution

Lynddahl, a leading manufacturer of microduct lines, has partnered with Tantec to enhance the quality and reliability of their production lines. This collaboration has resulted in the successful integration of Tantec’s PlasmaTEC-X solution into Lynddahl’s manufacturing process.

PlasmaTEC-X Solution Improves Microduct Line Quality

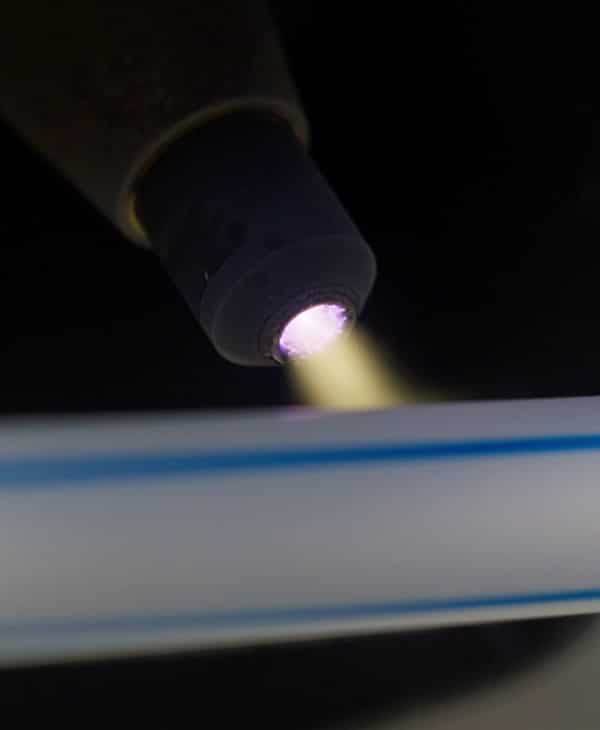

Plasma treatment with PlasmaTEC-X has been very effective in improving the adhesion of microduct lines for printing. The plasma treatment process cleans the surface of the microduct lines and modifies it at a molecular level, creating a more reactive surface that promotes strong adhesion of inks. This ensures that the printing process is consistent, and the resulting product is of high quality.

Testing Phase and Successful Integration

Before starting on the project, Lynddahl and Tantec had an agreement that allowed Lynddahl to test Tantec’s equipment in their production environment. This allowed them to assess the equipment’s benefits and see if it could solve their technical problems. The Tantec team provided equipment and support during the testing phase to ensure that they had a seamless experience.

The results were impressive, and Lynddahl quickly realized the potential benefits of installing Tantec’s PlasmaTEC-X equipment on their production lines. Since then, Lynddahl has deployed Tantec equipment on six production lines, and all of them are running smoothly with no downtime. The partnership has not only improved the quality of Lynddahl’s microduct lines but also increased their production capacity.

Benefits of Plasma Treatment with PlasmaTEC-X

The Tantec PlasmaTEC-X technology is the ultimate solution for surface treatment in the production of microduct lines. Plasma treatment improves the adhesion and wettability of surfaces, ensuring that coatings and adhesives bond more effectively. The equipment also removes contaminants such as oil, dust, and other impurities that may interfere with the bonding process.

What sets the PlasmaTEC-X technology apart is its ease of use and reliability. Lynddahl attests that they do not need to interfere with the equipment on a day-to-day basis. They just push the start button, and the equipment runs smoothly without any hiccups. The uptime is impressive, with minimum service requirements, allowing Lynddahl to concentrate on their core business of producing microduct lines.

In conclusion, the partnership between Lynddahl and Tantec has been a success, with the deployment of Tantec’s PlasmaTEC-X equipment resulting in a significant improvement in the quality and production capacity of microduct lines. Plasma technology is a powerful solution for surface treatment in the production of microduct lines. It provides an efficient and effective solution for improving adhesion and ensuring high-quality printing. Manufacturers who incorporate plasma treatment into their production process can expect better results and increased efficiency.

“Lynddahl has been very satisfied regarding the use of Tantec equipment also on this project, and there is no doubt that we would recommend them and also use Tantec going forward”, says Lars Bang Jønsson, Head of Technology at Lynddahl.

Recommendation and Rental Option

Tantec understands that investing in new equipment can be a significant decision for any company. That’s why Tantec offers the option to rent our standard equipment for testing purposes before committing to a purchase. This allows companies to assess the benefits of Tantec’s equipment in their own production environment and determine whether it is a suitable fit for their needs. The rental option provides an opportunity to test the equipment on a trial basis, ensuring that it meets the company’s expectations and requirements before committing to a purchase. This approach is an excellent way for companies to make informed decisions about equipment investments and can help ensure a successful outcome.