Plasma-pretreatment in the automotive industry

As a leading international supplier and partner of automobile manufacturers, Valeo plays an important role, also in Germany: With 28 sites, eight research and development centers and 7200 employees, the French group generates one third of its turnover there. Besides brakes and clutch hydraulics (made of plastic), actuatorics – a branch of gear and drive technology – are part of Valeo’s main business. In these key technologies, Valeo is one of the market leaders – in part thanks to state-of-the-art assembly lines that include a plasma activation by Tantec, which amongst other things improves adhesive bonding. The major advantage of a surface pretreatment with atmospheric plasma: Since no counter electrode is necessary, the substrate does not need to be additionally grounded, which allows for targeted processing.

“In electromagnetic actuatorics, it is decisive that magnets stay in place. Plasma activation must be reliable and provide maximum adhesion here.”

Engineer Peter Ruppert explains that Valeo counts on a PlasmaTEC-X system – a Tantec standard product – in this future-oriented technology because of its high-quality standards: “In electromagnetic actuatorics, it is decisive that magnets stay in place. Plasma activation must be reliable and provide maximum adhesion here.” And what other criteria apply when choosing a supplier of atmospheric plasma? The process technician tells us that, besides the lowest possible acquisition and maintenance costs, reproducibility is a decisive factor. “A plasma cleaning system should not only be safe, efficient and affordable, but also deliver consistent results.”

Tantec’s plasma system fulfills all the crucial requirements because it is compact and lightweight, failure and maintenance free and keeps pace with high production speeds. Another benefit according to the engineer: “It’s easy to install, user-friendly and flexible in use.” The background to this is that, thanks to the combination of the AirTEC system with a universal power supply, no adjustments are necessary.

Suitable for use with robots, robust and scalable: Customized extraction systems by FlensTech

The longstanding cooperation with Tantec also paid off for Valeo when it came to the undesired consequences of plasma and corona treatments. A contact to Tantec’s sister company FlensTech, which has developed special extraction systems for plasma nozzles preventing the propagation of noxious gases at their point of origin, was established. Especially ozone and oxide gasses are considered as problematic because they can harm human health and cause corrosion of machine parts. The innovative solution by FlensTech: A customized extraction system, which precisely extracts the nitrous gases during the use of atmospheric plasma only a few centimeters from their point of origin and leads them to the outside. This high-precision extraction of emissions requires far less energy than processes which extract large parts of the air surrounding the machine: Depending on the speed and form of the substrate, the air consumption of FlensTech’s extraction system only lies somewhere between 200-400 m3/hour.

“The FlensTech extraction hood can be integrated into our machine equipment as a new component without any extra costs.”

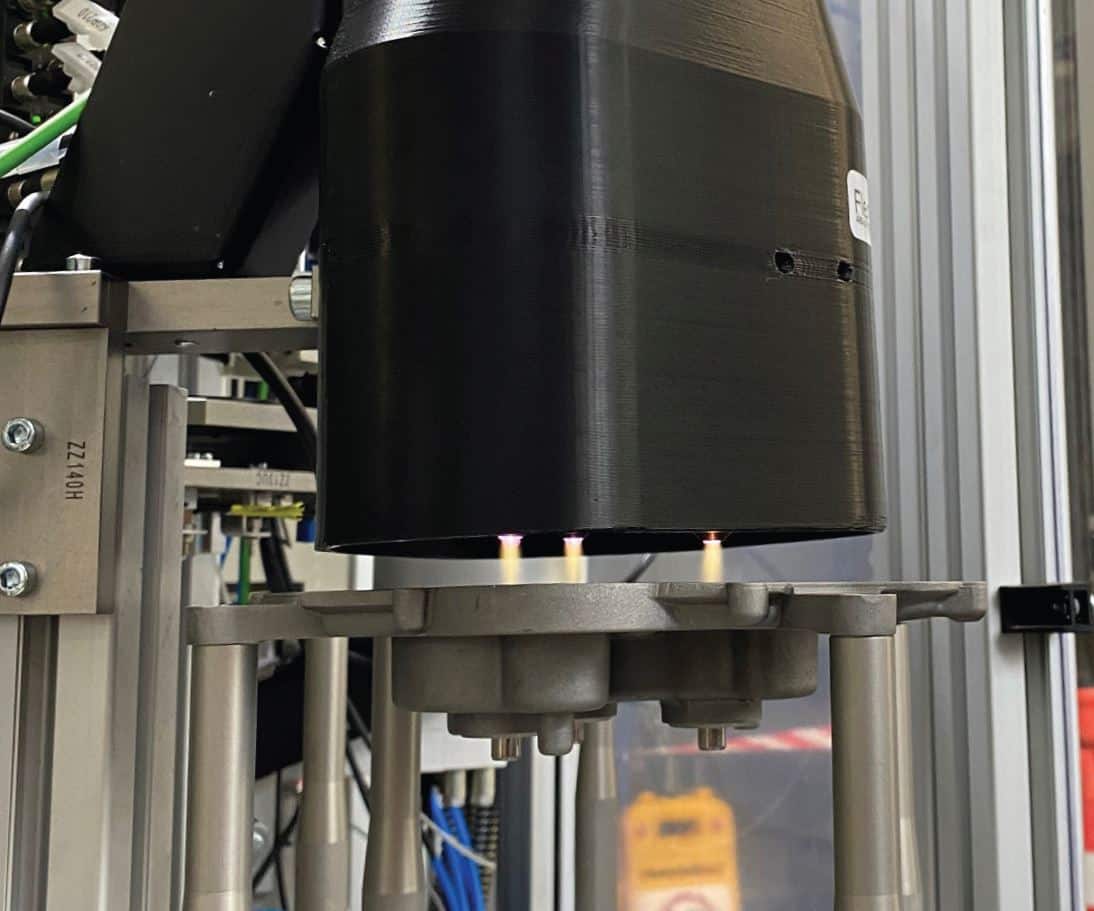

In the case of Valeo, FlensTech met a new challenge: Since the plasma system and the plasma nozzles are assembled in a triangle and there is no place for the extraction hood left next to the treated substrates, a special construction was necessary. So, the FlensTech team, which holds more than three decades of experience in the plastics industry, designed a custom-made extractor in close cooperation with Valeo: A tailor-made design, which is suitable for the use with robots, robust and scalable and has passed extensive feasibility tests at Technikum Flensburg. During these tests, the temperature development in the extraction pipe is determined under real conditions. As a part of this service, every customer receives all information about the volume flow before commissioning, so they do not have to evaluate the optimum suction power for emitting ozone and nitrogen themselves.

Besides safety, efficiency and savings on power, costs and time thanks to individual package solutions, engineer Ruppert mentions a further advantage of the extraction system: “The specially designed extraction system can be integrated into our machine equipment as a new component without any extra costs.” Other extraction systems require an additional external control system, Ruppert explains. “We would be able to integrate that into our machine control, but it would imply additional expenses, which we can save by using the FlensTech extraction system.”