Surface treatment of cables for the military aircraft industry

One of the world’s largest military aircraft manufacturers recently found that Tantec’s corona technology has outlasted the longevity of the electronic components used to create corona. The CableTEC manufactured by Tantec has been in daily use for 25 years.

The internal electronic components for the generator have significantly changed during the last 25 years and it was impossible to obtain the required spare parts for maintenance. With over 50,000 hours of surface treatment of Teflon cables in different variants, Tantec’s customer had no doubt in reinvesting in another solution from Tantec based on our

The internal electronic components for the generator have significantly changed during the last 25 years and it was impossible to obtain the required spare parts for maintenance. With over 50,000 hours of surface treatment of Teflon cables in different variants, Tantec’s customer had no doubt in reinvesting in another solution from Tantec based on our

quality and ROI.

An airplane typically has a life span of 20-30 years, and with a Tantec solution the customer was able to meet the high demands for longevity and reliability for surface treatment of cables. In connection with replacing the Tantec solution, the customer examined alternative solutions such as laser printing, but investment in laser print systems proved to be almost twice as expensive as a CableTEC solution with inkjet printer. The decision was to invest in a new Tantec solution because of Tantec’s extremely stable performance and zero breakdowns over 25 years. A new specially designed CableTEC solution was chosen combined with a standard inkjet print solution.

The new Corona solution is designed to handle all new demands of our customer as it related to the processing speed of the PTFE cables. The unit is enhanced to allow for more flexibility on the surface treatment of different variants and sizes of the cables.

The customer’s high demands for throughput on Teflon cables along with Tantec’s service and reliability were crucial for choosing a new CableTEC solution.

Corona Treatment of Cables

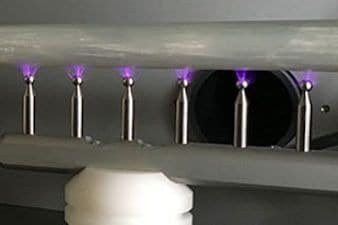

The CableTEC is a unique and cost-effective method for modifying polymer cable insulations (PE, PP, and PTFE), resulting in adhesion property optimization of printing inks and coatings onto the cable. The in-line treating system has been

specifically designed by Tantec to facilitate easy installation to new or existing production lines. A complete system includes a high frequency generator, high voltage transformer, air-cooled electrodes, ozone filter and a customized stand alone or bench-top treating station. CableTEC conforms to CE regulations and carries the CE-marking.

The CableTEC features:

• 360° non-contact treatment

• Treatment of standard cable, tubes and profiles

• Fully shielded treating station

• Zero-speed control

• Integrated “watt-density” control

• High-speed treatment

• Availability for “hard to treat materials”

Read more about CableTEC