Plasma treatment provides better adhesion and increased line speed

Customer

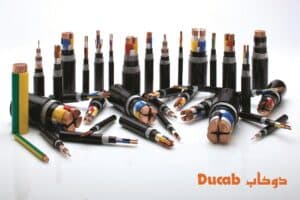

As one of the largest manufacturing businesses in The Emirates, Ducab provides world-class solutions to the global energy sector. Since 1979, the company has expanded from its home markets and now has a footprint in 45 countries across the Middle East, Africa, Asia, Australia, Europe, and the Americas. With an increasing focus on renewables, the company produces advanced copper and aluminum wire and cable products as part of its end-to-end energy solutions.

Challenge

For surface treatment on Ducab’s solar cable, they wanted an improvement in adhesion of the printed ink. In addition to the purpose of improving ink printing on the surface of the cable, Ducab also had a requirement to improve the productivity to meet market demand and achieved a 225% improvement with the Plasma treater.

Technology

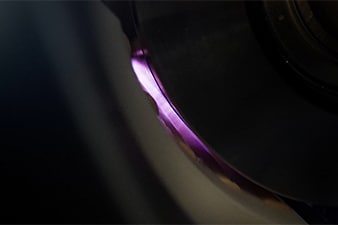

Tantec’s plasma treatment systems provide substantial flexibility in the treatment of a wide variety of materials used in the cable and wire industry and is a critical process in solving adhesion problems. Tantec’s plasma treaters can treat cable and wire across their complete length with superior one-pass coverage and consistency. Plasma treatment chemically roughens the surface, allowing it to ’grab onto’ the ink being applied to the cable or wire. The resulting chemical bond that occurs with the cable or wires surface is stronger than a simple mechanical bond.

Solution

Ducab decided to invest in Tantec’s PlasmaTEC-X. With this solution, Ducab achieved improved adhesion while increasing the line speed with the same equipment. Implementation of Tantec’s plasma treater was a remarkable success:

” Implementation was fantastic and the plasma treatment unit is very compact in size and very user friendly”, says Deepak Dattatraya, Ducab.

Innovative surface treatment solutions for the flexible electronics of the future

Innovative surface treatment solutions for the flexible electronics of the future infinityPV is a Danish company with a strong international profile, specializing in the development and production of advanced solutions for printed and flexible electronic devices. With...

Enhancing quality and sustainability with Tantec’s surface treatment solutions

Enhancing Quality and Sustainability with Tantec’s Surface Treatment Solutions IntroductionPrintmasters, the exclusive decorator and value-added services provider for XD Connects, specializes in offering over 20 advanced decoration techniques and a wide array of...

Autoform boosts production efficiency with innovative plasma treatment

Autoform boosts production efficiency with innovative plasma treatmentAutoform, one of Europe's leading manufacturers of vacuum formed products, continues to push the boundaries of innovation in its production processes. Specializing in products such as boot lids,...