Surface Treatment of Catheters

A catheter is a thin, flexible tube that is inserted into the body to perform a medical procedure or to drain fluids. It can be made of various materials such as silicone, PTFE, Pebax, latex, PU, or a variety of different plastics.

Typically, these materials have low surface energy which presents challenges for bonding, coating, and printing processes. Durability and quality are important factors in manufacturing medical devices and an efficient surface treatment is required to optimize these processes.

How

Plasma and Corona Surface Treatment modifies the surface using an electrical discharge which creates a high surface energy ready enhancing the ability for glues, inks, and coatings to wet out and adhere better.

Plasma and Corona Treatment modifies the top layer of the plastic molecules, essentially chemically etching the surface without changing the look, feel, or structural integrity of the part.

Why

Surface treatment of catheter tubing is necessary to ensure that your coating or ink stick to the surface. We have been solving adhesion problems on catheter tubing for over 45 years using the most advanced surface treatment technologies available – Plasma and Corona treatment.

Corona treatment – Partial treatment prior to gluing

A major manufacturer of catheter tubing based in France encountered a challenge and sought Tantec’s expertise. The issue was that they were unable to achieve adequate adhesion between the shaft of a catheter tube and the tube itself. Tantec provided a solution that involved a partial corona treatment of the tubing. By treating only, the end of the tube prior to applying the adhesive and attaching the shaft, a robust bond between the components was achieved, greatly improving the product’s safety.

Corona treatment – in-line production

To meet the needs of an international customer, it was necessary to treat the entire surface of their catheter tubes before printing. This had to be done during a continuous production process. Tantec successfully customized a corona treater that fits perfectly into this production line, allowing for uniform treatment of the entire surface of the catheter tube. This development enabled the customer to achieve their desired outcome with efficiency and precision.

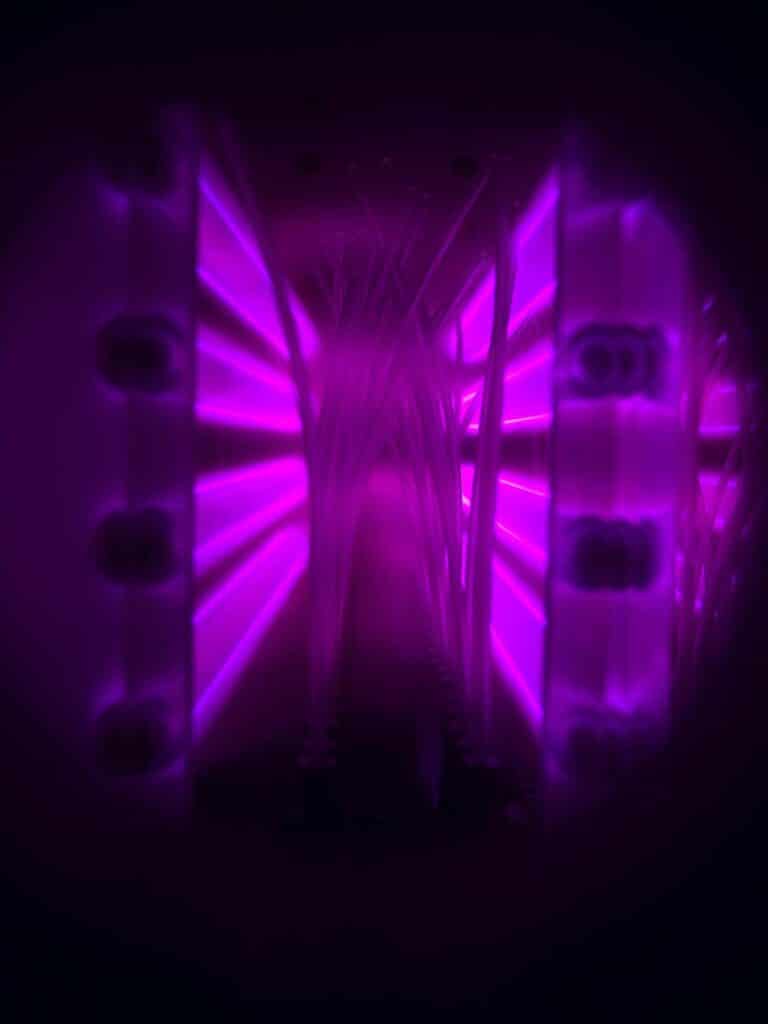

Vacuum plasma prior coating

A catheter tube manufacturer based in Denmark was looking for a customized solution for treating semi-finished catheter tubes. The tubes had been extruded and cut into pieces, and the customer required complete vacuum treatment before coating. This posed a unique challenge that required innovative thinking from the engineering team at Tantec, resulting in the development of a customized vacuum chamber capable of treating 90 catheter tubes simultaneously. This solution allowed the customer to optimize their production process, thereby improving their efficiency and overall output.

Free report and analyze.

Choosing the most suitable treatment method for a specific task can be challenging without a comprehensive analysis of the entire production process. Determining the optimal method depends on factors such as whether the surface will be glued, printed, or coated, and whether complete or partial surface treatment is needed. Tantec can provide a tailored treatment solution for new or existing production processes by conducting a detailed analysis of the process. This ensures that the treatment solution is optimized for the specific requirements of the job at hand.