Cases

Cases

Everyday thousands of Tantec’s plasma and corona surface treatment solutions are counted on in production facilities throughout the world. Below you will find a number of cases where Tantec’s surface treatment solutions are being used everyday to solve our customers adhesion problems.

Innovative surface treatment solutions for the flexible electronics of the future

Innovative surface treatment solutions for the flexible electronics of the future infinityPV is a Danish company with a strong international profile, specializing in the development and production...

Enhancing quality and sustainability with Tantec’s surface treatment solutions

Enhancing Quality and Sustainability with Tantec’s Surface Treatment Solutions IntroductionPrintmasters, the exclusive decorator and value-added services provider for XD Connects, specializes in...

Autoform boosts production efficiency with innovative plasma treatment

Autoform boosts production efficiency with innovative plasma treatmentAutoform, one of Europe's leading manufacturers of vacuum formed products, continues to push the boundaries of innovation in its...

How Flonidan optimized a crucial aspect by 50%

Flonidan, a leading developer and manufacturer of gas meters for the European and Asian markets, has experienced significant production improvements by implementing Tantec's plasma surface treatment...

Venture Automation optimizes end customer’s production with Tantec solution

Venture Automation, a leader in the design and manufacture of automation equipment for the automotive glass industry, has achieved remarkable improvements in their customer's production processes...

Hill Machinery reduces costs and improves the environment with Tantec technology

Hill Machinery, a leading supplier of secondary equipment to the automotive industry, has helped their customer achieve significant cost savings and environmental benefits by implementing the Tantec...

How Sono-Tek improves the quality of thin film coatings with Plasma and Corona technology

Since 1975, Sono-Tek has been a global leader in ultrasonic coating solutions, offering advanced and patented thin-film coating systems. These systems provide comprehensive solutions to complex and...

Tantec’s innovative ozone surface treatment helps create outstanding outdoor gear

If you have ever seen an American barbecue (in real life or in film), you may have noticed their rugged coolers with the foamy insides that keep beer and soda cold. Well, chances are – especially if...

ProCobot explores new possibilities with Tantec’s Plug & Play Plasma solution

At a time when automation and efficient solutions are essential to maintain competitiveness in quality-driven industries, the collaboration between Polish ProCobot and Tantec has marked a...

Tantec delivers customized solution resolving inkjet printing adhesion challenges on PP plates for Czech customer

Tantec has delivered a solution tailored 100% to a Czech customer’s production line. The customer had significant issues with adhesion of their inkjet printing on PP (polypropylene) plates.

PlasmaTEC-X is an essential part of an accurate foam dosing technology

The British manufacturer ASD Lighting PLC has since 1982 designed, developed, and manufactured high quality lighting products.

Lynddahl improves microduct quality with Tantec’s PlasmaTEC-X solution

This collaboration has resulted in the successful integration of Tantec’s PlasmaTEC-X solution into Lynddahl’s manufacturing process.

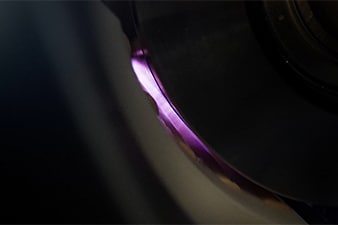

Treating Catheters with Vacuum Plasma prior to coating improves adhesion

Vacuum Plasma treatment improves bonding properties. By increasing the surface energy of catheters using vacuum plasma treatment the bonding properties improve – thereby adding extra safety and reliability to the product.

Surface Treatment of Catheters

Surface treatment of catheter tubing is necessary to ensure that your coating or ink stick to the surface. We have been solving adhesion problems on catheter tubing for over 45 years using the most advanced surface treatment technologies available – Plasma and Corona treatment.

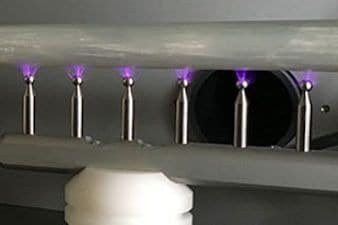

High tensile strength after plasma treatment of Needle Hubs

Tantec delivered a plasma treatment solution for 11 lines for the production of needle hubs. To each of these lines, we provided two plasma nozzles to treat the needle hubs, before placing the needle. The Plasma nozzles treat 20 needle hubs per 1.4 seconds.

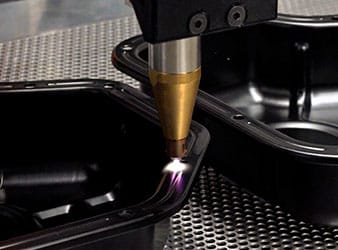

Plasma-pretreatment in the automotive industry

As a leading international supplier and partner of automobile manufacturers, Valeo plays an important role, also in Germany: With 28 sites, eight research and development centers and 7200 employees, the French group generates one third of its turnover there.

Customized corona treater fulfills all wishes for surface treatment of polyethylene foams

Our customer in the Czech Republic C. Connect s.r.o. has just invested in a Tantec Corona treater for surface treatment of polyethylene foams with variable thicknesses. C. Connect core focus is on converting and product finishing for several industries like automotive, appliances, packaging, electronics, etc.

Richards Wilcox Garage Doors Benefit from Tantec’s Corona Treatment

Richards Wilcox Garage Doors Benefit from Tantec’s Corona Treatment For many people, the garage door is the second entrance to the home. Before you can walk through your front door, you park your...

Improved adhesion of metal and plastic parts for world-renowned producer of designer fittings

The Danish company VOLA produces high quality fittings and accessories.

At VOLA, quality is a part of the company culture. Only perfect is good enough. It takes many years of training and experience to find the right surface and angle of inclination for a part to be brazed perfectly .

Improved adhesion for the most advanced tracking unit on the market

Trusted A/S is a Danish company specializing in high-tech and advanced tracking systems. Their system uses an advanced technology with intelligent sensors. Trusted trackers are the most developed, resistant, and adaptable tracking units on the market and are used in a wide range of industries, such as…

Plasma treatment provides better adhesion and increased line speed

As one of the largest manufacturing businesses in The Emirates, Ducab provides world-class solutions to the global energy sector. Since 1979, the company has expanded from its home markets and now has a footprint in 45 countries across the Middle East, Africa, Asia, Australia, Europe, and the Americas.

Plasma cleaning in the cable industry – Tantec scores with high speed and reliability

Whether it’s about robotics, the automotive industry, or the power input of wind turbines: People and machines around the globe are supplied with power and information by billions of cables and wires. They form a worldwide infrastructure and are the lifelines of a digitized world, with enormous data streams flowing through them.

The Impossible Trio, Solved: Greener, Cheaper and Stronger Adhesion Made Possible on an Industrial Scale

A new partnership between Tantec and the American company Reliabotics has paved the way for a superior industrial adhesion process. This process is not only cheaper than traditional ones, but also ensures stronger adhesion whilst being easier on the environment.

LeakTEC Detects Micro Pinholes in Medical Equipment

MGS Manufacturing is a long-time customer of Tantec’s. Throughout the years, many Tantec systems have been deployed for MGS customers as part of four unique medical applications. MGS uses Tantec’s LeakTEC tools for leak testing and to identify any micro-holes in the products they produce.

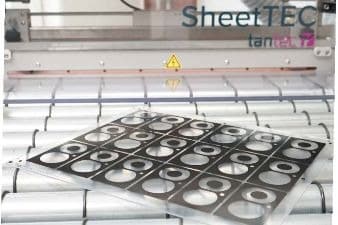

SheetTEC saves time and money when printing directly on PEHD sheets

Tantec’s SheetTEC corona system has made a significant difference for the Slovakian company Kodan Plast since the spring 2021. Kodan Plast specialites in processing plastics, including sawing, milling, and turning of large and small items for many types of quality-conscious industries.

Tantec Corona surface treatment replaces chemical treatment of sprayers

Safe Reflector is one of the largest manufacturers of light reflecting products and sprayers in Northern Europe. The company offers a wide range of pocket sprayers. Their selection of sanitizer sprayers inclu-des hand sprays and sun care, amongst others.

Flexible Corona treater system for treating of 3-Dimensional glass and glass sheets

A major European glass producer selected a Tantec corona treatment solution to improve the bond strength of their coating to glass sheets. This customer needed a solution that can treat both flat sheets and 3D shaped glass in the same machine.

Standard Corona Treatment Unit for Sheets

Tantec has developed a standard corona system known as SheetTEC, for surface treatment of sheets. The purpose of surface treatment of polymer based materials is to increase surface wettability through electrical discharge. The low surface energy of polymer based substrates often leads to poor adhesion of inks, glues and coatings.

Optimized adhesion of digital print on sprayers

Optimized adhesion of digital print on sprayersOne of Eastern Europe's largest producers of quality sprayers in credit card format with a range of no-mosquito, antibacterial, sun care, and much more...

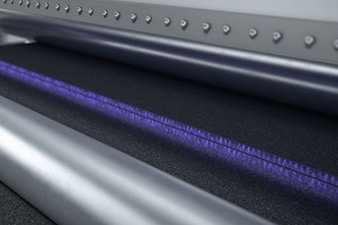

FoamTEC – Corona treatment of foam and board

Due to low surface energy, boards, foam, glass, plastic sheets and corruga-Due to low surface energy, boards, foam, glass, plastic sheets and corruga-ted materials are difficult to bond to.

Tantec Plasma Treatment Crucial for Production of LED Navigation Lights

Lopolight is a leading manufacturer of navigation lights for boats, ships, ferries, and other vessels. The Danish company is located in Humlebæk, north of Copenhagen, and develops and produces complete LED navigation lighting systems which meet the extremely demanding standards of the US Cost Guard and the army.

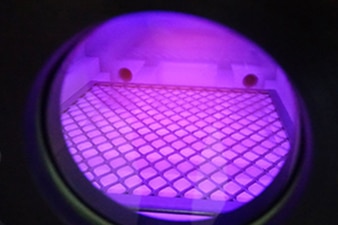

How the Functionality of Graphene Changes with Plasma Treating

Several years ago, Tantec entered into an agreement with Haydale for the development and supply of plasma chambers. Based in the UK, Haydale has made a name for itself for enabling technology for the commercialization of graphene.

Fully automatic leak detection system from Tantec makes a big difference for a customer

This customer required high speed leak detection of a small plastic medical component. The client historically uses a pressure test to check for holes in the plastic injection molding.

Corona Treatment of Glass Sheets Prior to Coating Application

Tantec’s SheetTEC unit is a standalone and inline surface activation method used by many of the leading producers and manufacturers of glass within EU and the United States.

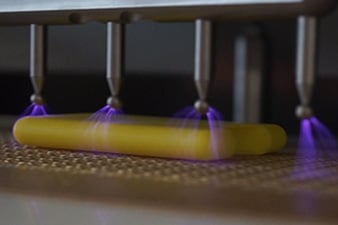

50 years of experience in surface treatment for packaging industry

Tantec’s PlasmaTEC-X is the ideal solution for surface treatment in the packaging industry. With more than 50 years of experience and a focus on environmental friendliness and cost efficiency, Tantec can offer knowledge, expertise and the widest range of solutions for surface treatment.

Customized Leak Detection System for the Medical Industry

Tantec recently delivered a LeakTEC system to a large medical device manufacturer. The Tantec LeakTEC system we able to meet the customers high expectations and system requirements.

Having difficulty bonding to glass?

Bonding or sticking material to glass can be a difficult and complex procedure for many. However, Tantec has been operating in this business for over 40 years and has extensive practical experience.

Surface treatment of cables for the military aircraft industry

One of the world’s largest military aircraft manufacturers recently found that Tantec’s corona technology has outlasted the longevity of the electronic components used to create corona. The CableTEC manufactured by Tantec has been in daily use for 25 years.

In-line treatment of Automotive Sealing Products

Top quality adhesion of printing inks, adhesives or coatings on polymer materials, such as PE, PP, PS, EPDM-rubber and other substrates, is a common requirement throughout the plastic and rubber processing industry.

Improved adhesion for one of the largest manufacturers of ski bindings

The French ski binding manufacturer Look is one of the most famous and respected brands within the ski genre. Look’s bindings represent the perfect combination of security and performance and are behind some of the most optimal solutions on the market.

Vacuum Plasma Treatment Greatly Improves Adhesion for Leading Car Manufacturer

Car manufacturers across the globe are looking for innovative methods to improve the quality of their product offerings and to give customers exactly what they are looking for. In their effort to get the best product offerings, they are incorporating different manufacturing techniques.

Impressive surface treatment with Plasma replaces unreliable flame treatment

After many years, the Italian machine manufacturer GPE Ardenghi srl has replaced flame treatment with plasma treatment in their screen printing machines.

Tantec LeakTEC solution is vital for diagnosis

Leak detection is vital for multi well plates for use in diagnostic systems. Tantec has just delivered a LeakTEC system to a manufacturer of diagnostic systems for analysis of diseases, including Covid-19.

Improved surface adhesion for COC and COP Prefilled Syringes

The medical and pharmaceutical industry has shown an increasing tendency towards the use of plastic materials Cyclo Olefin Polymer (COP) and Cyclo Olefin Polymer Co. (COC) in the production of plastic Prefilled Syringes.

SheetTEC improves the surface tension of acrylics and polycarbonates for adhesion

It is often necessary to coat sheets as part of the manufacturing process. In order for liquid adhesives, glues, coatings or inks to adhere to the surface of cast, molded or extruded plastics we must first modify the surface.

Corona Can Improve the Production Process of Plastic Lenses

Plastic materials for ophthalmic lenses have seen continual developments, and for this reason, have gradually replaced glass materials. Today, most corrective lenses are made of thermoplastic and thermosetting resins.

Surface treatment of plastic pipes – inside and out

Plastic piping is used in a wide variety of applications and across a range of different industries. The three main types, PE, PEX, and PP, share one basic characteristic – low surface energy.

Surface Treatment with Ozone

Tantec has developed their OzoneTEC System to treat the inside of products such as surfboards, coolers, ice boxes, jacket pipes, small boats etc. – products that consist of fiberglass on the outside and foam on the inside – also called sandwich construction.